Investigación

En T2CM desarrollamos soluciones científico-tecnológicas para transformar relaves mineros en materiales de construcción, optimizando desempeño mecánico, procesos de fabricación y escalamiento para aplicaciones reales.

Publicaciones

2025

Impact of mixture design and production parameters on the crushing strength of cold-bonded alkali activated aggregates made from iron tailings

Keywords: Alkali-activated materials; Iron mine tailings; Factorial experimental design; Concrete

Estefanía Loyola

Claudia Eugenin

Felipe Vargas

Alvaro Videla

Iván Navarrete

Abstract

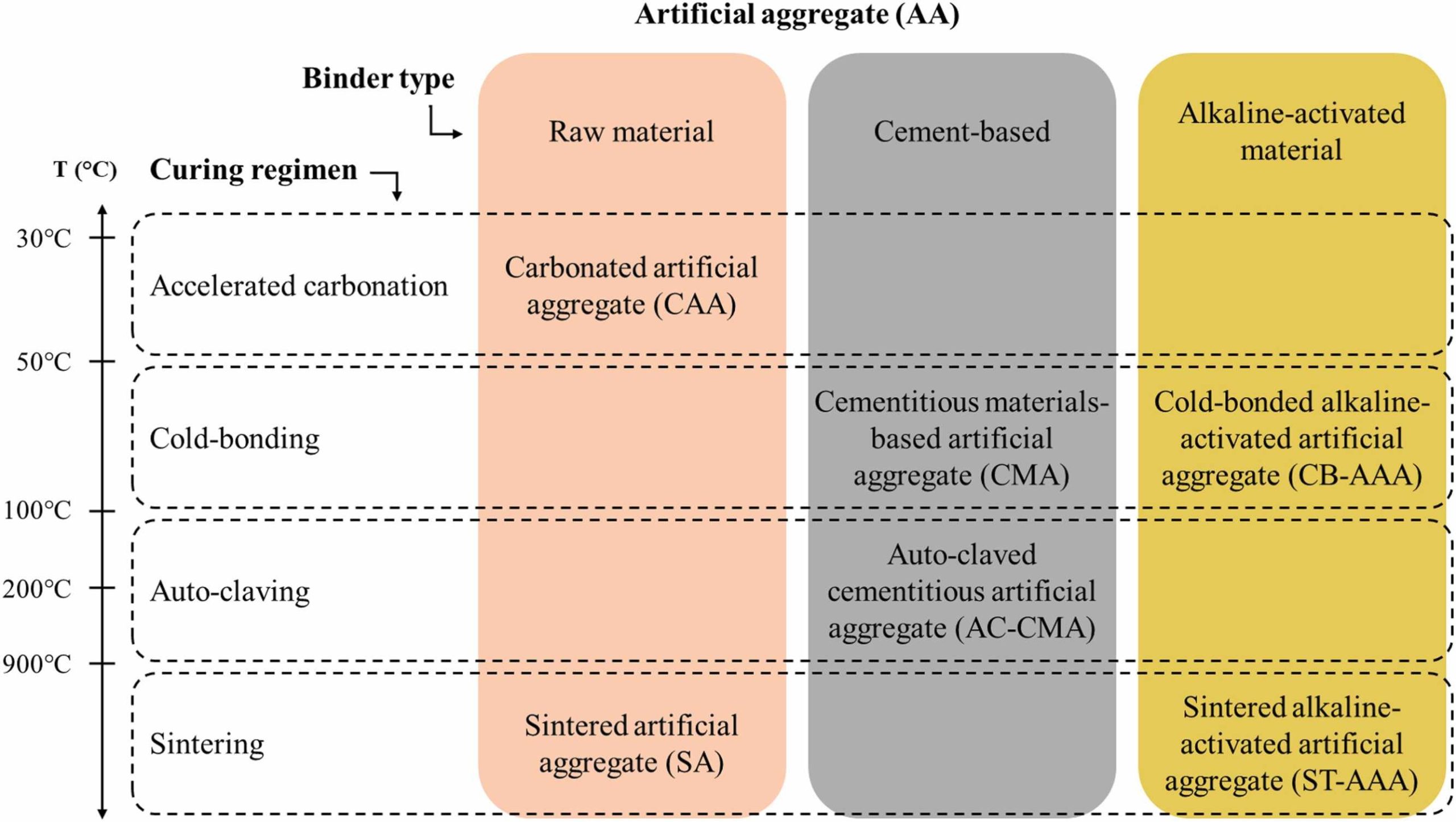

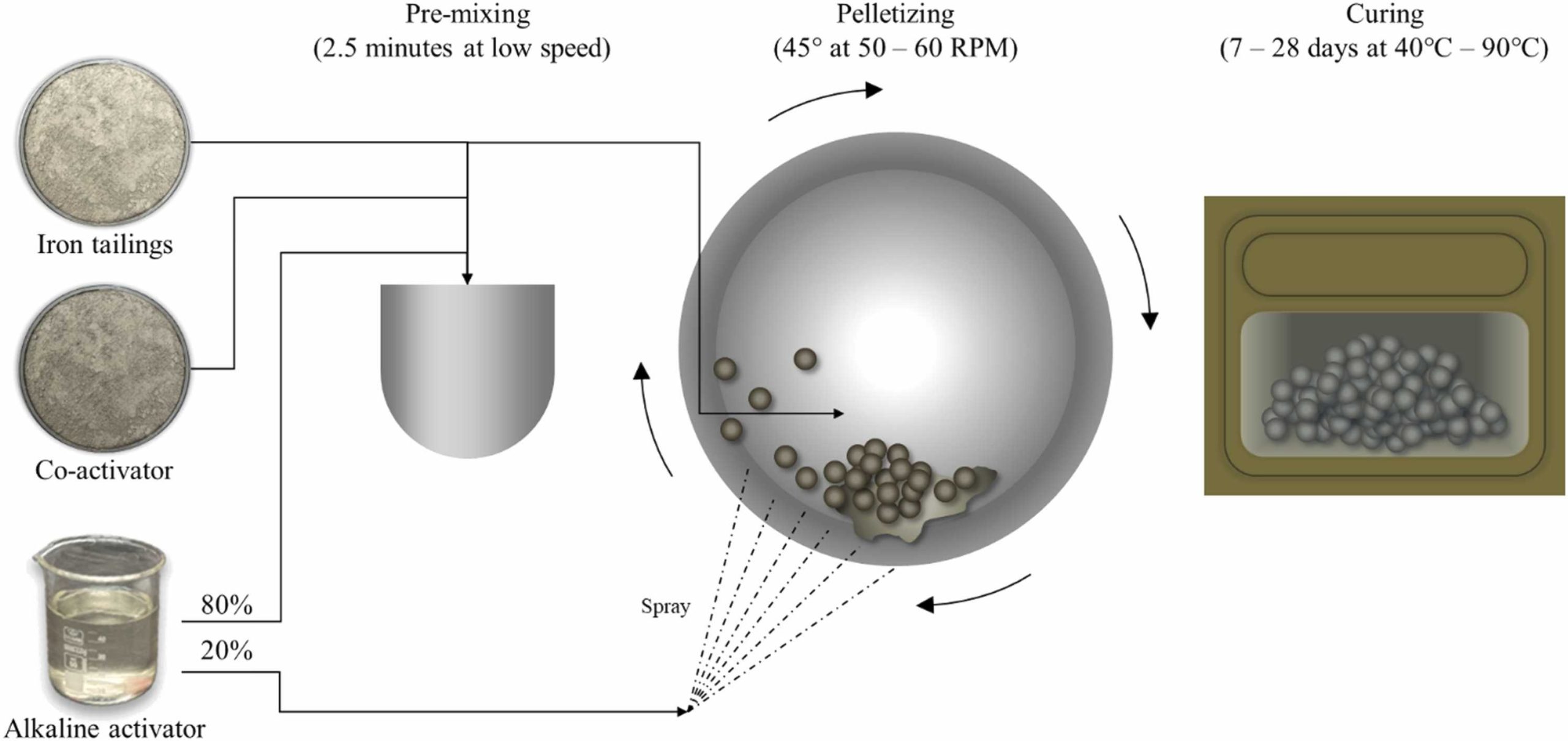

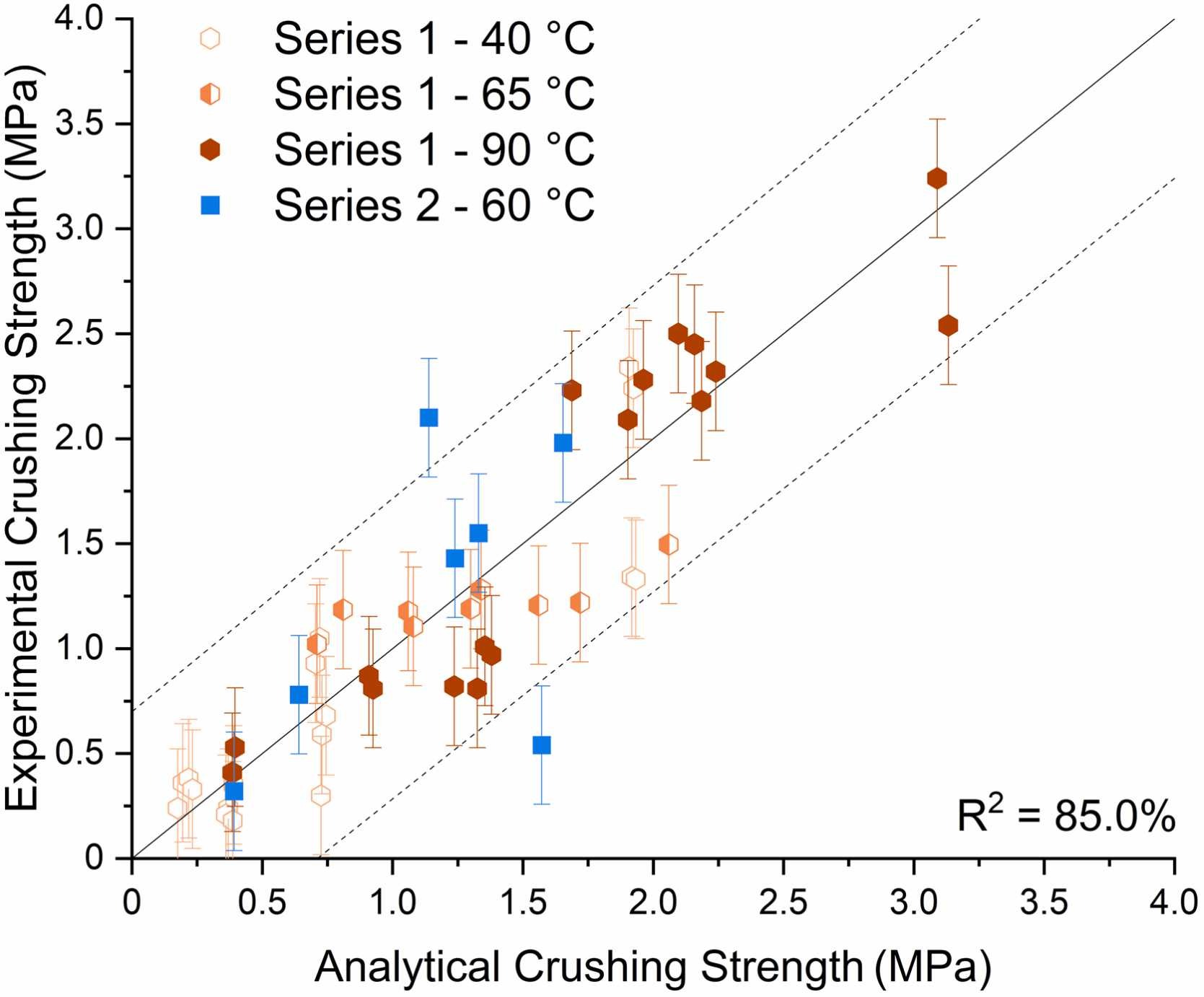

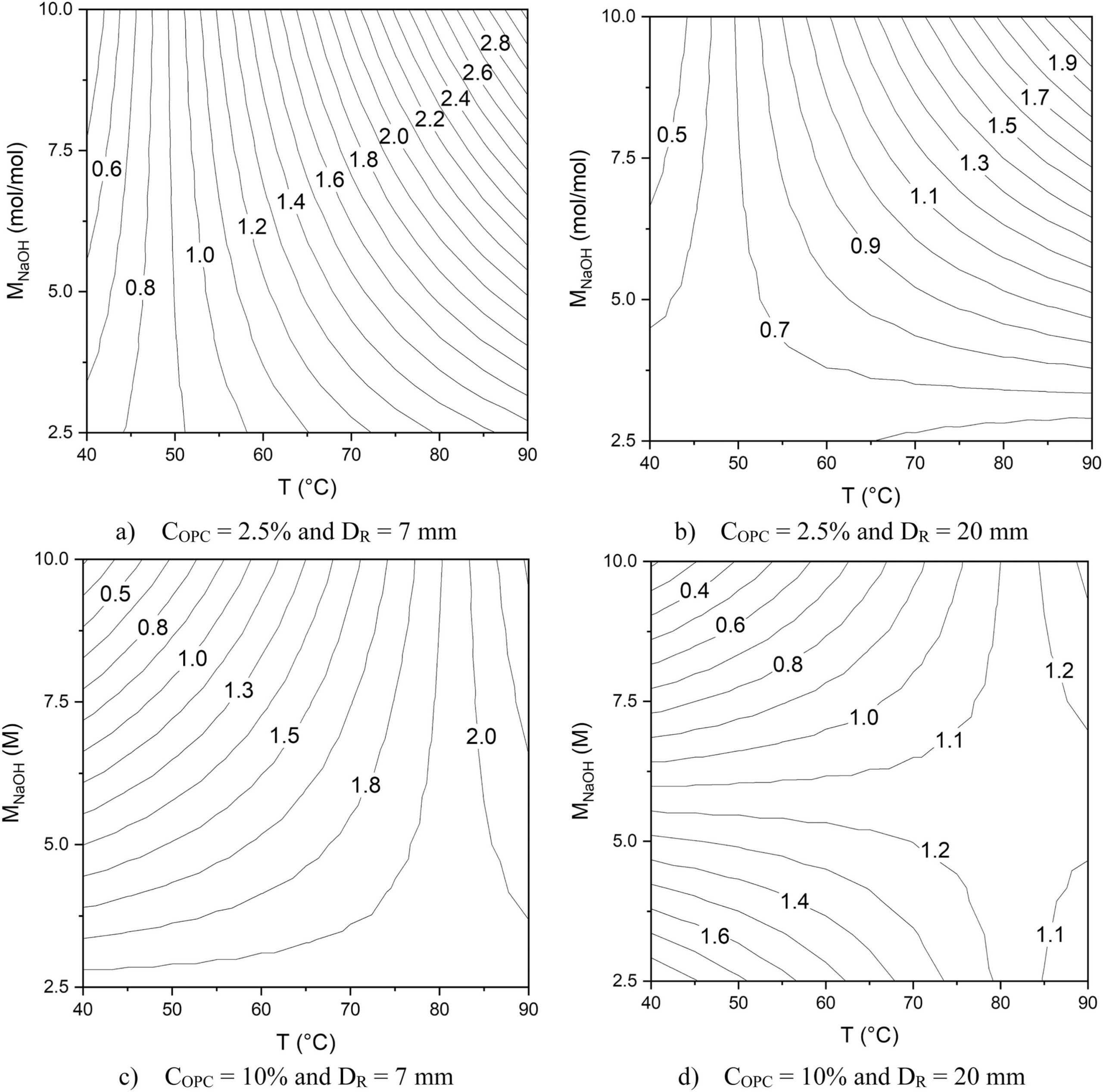

This study explores the production and performance of cold-bonded alkali-activated artificial aggregates (CB-AAA) made from highly crystalline iron tailings, a low-reactivity mining by-product. A factorial experimental design was used to assess the influence of five key parameters on crushing strength: aggregate particle size, alkaline activator molarity, co-activator dosage, curing temperature, and curing time. The resulting aggregates exhibited bulk densities from 824 to 1002 kg/m³ , water absorption between 14.78 % and 25.68 %, and crushing strengths ranging from 0.18 to 3.24 MPa. A second-order polynomial regression model was developed and validated, identifying curing temperature as the most significant factor. To evaluate structural applicability, concrete specimens were prepared with 30 % and 100 % replacement of natural coarse aggregates. Higher-quality CB-AAA mitigated compressive strength losses, with partial replacement mixtures retaining up to 60 % of the reference strength. These results demonstrate the feasibility of using iron tailings in low-carbon construction materials despite the low reactivity of these waste materials, and they offer new insights into the role of mixture design and processing conditions in optimizing the performance of CB-AAA for concrete applications.

2025

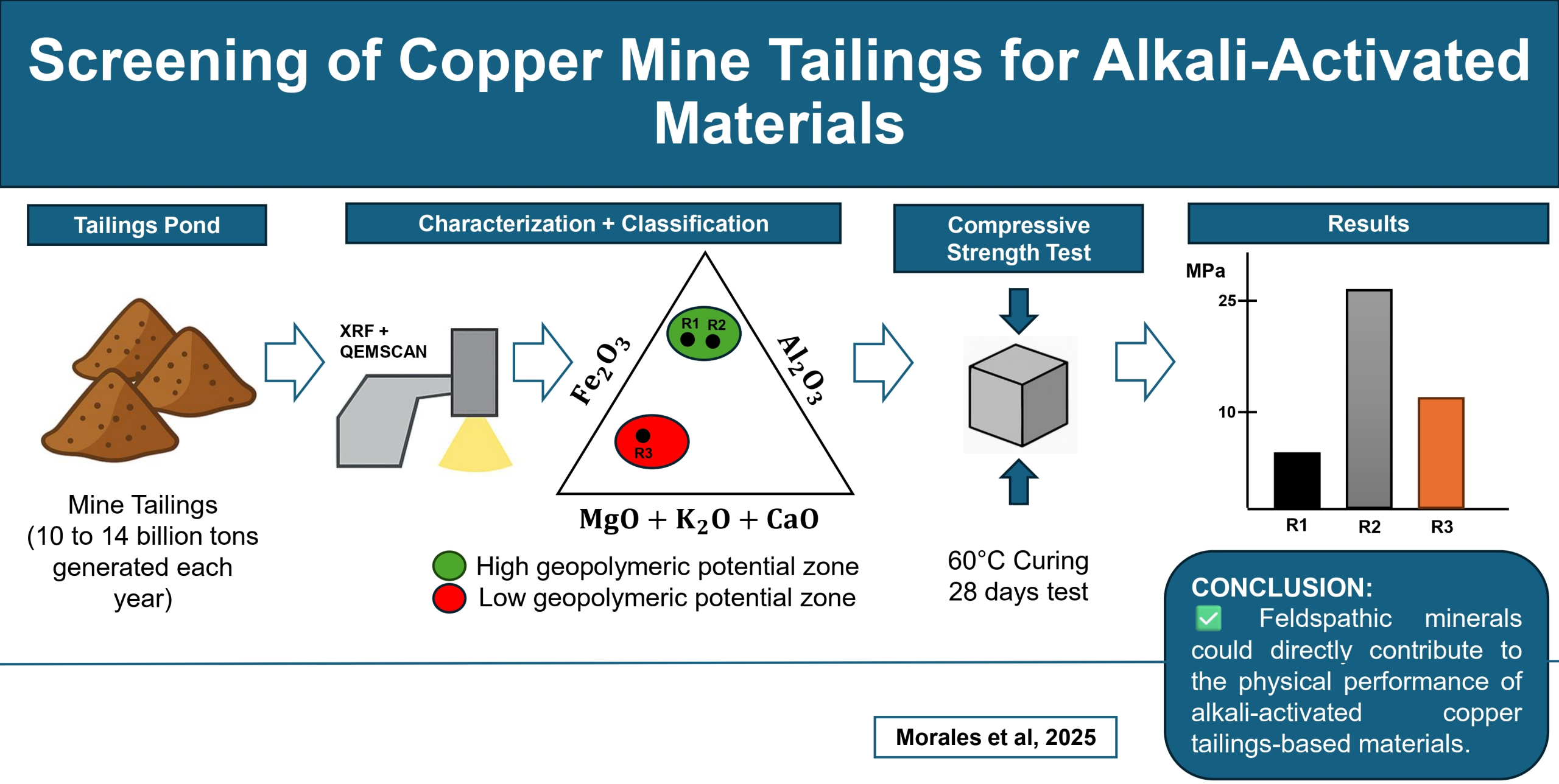

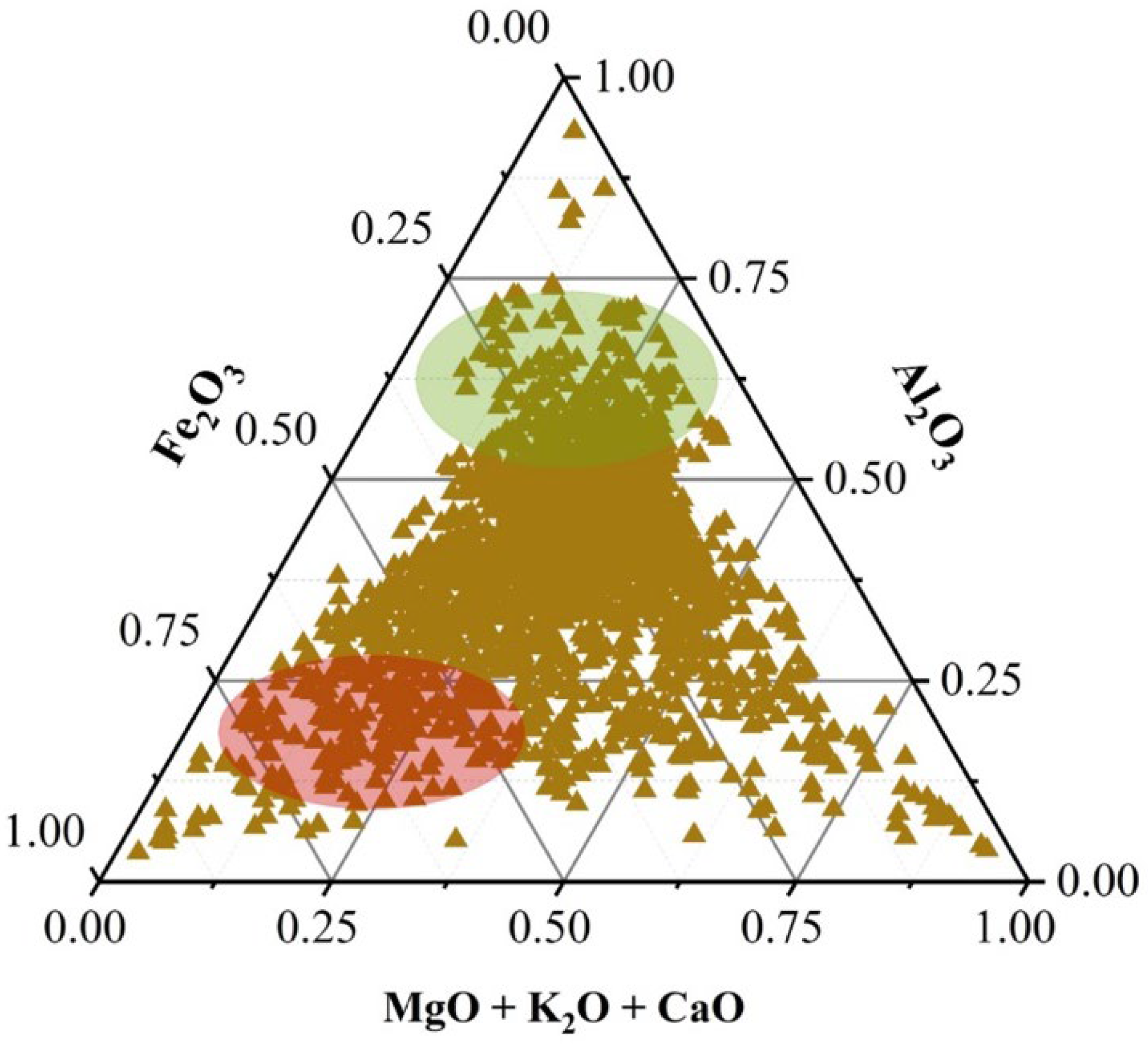

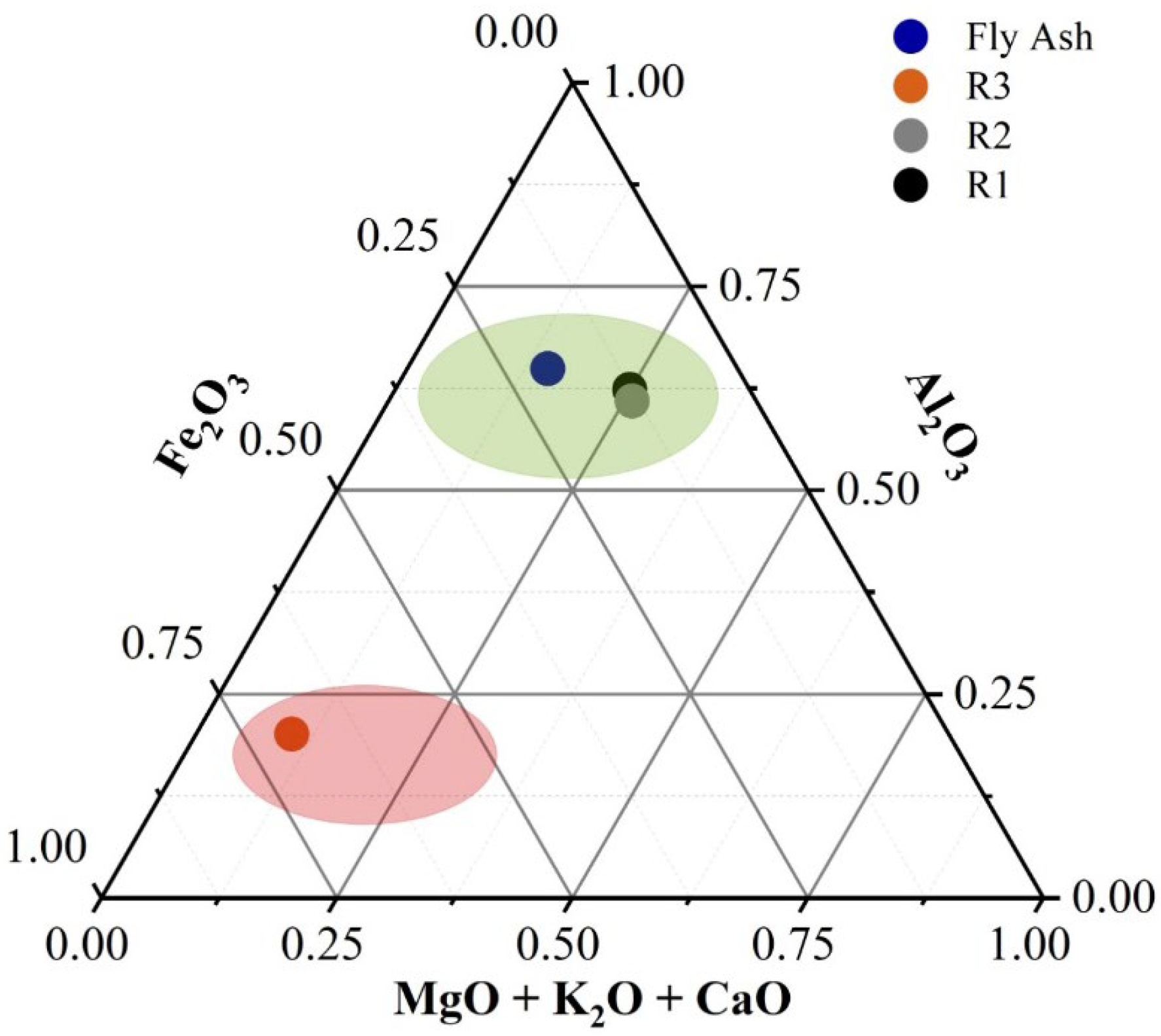

A Study on Copper Mine Tailings to Be Used as Precursor of Alkali-Activated Materials for Construction Applications

Keywords: geopolymers; tailings; copper mine tailings; alkali activation; mineralogy; ternary diagrams

Luis Morales-Castro

Estafanía Loyola

Matias Castro-Quijada

Felipe Vargas

Iván Navarrete

Claudia Eugenin

Carlos Marguardt

Alvaro Videla

Abstract

This research presents a novel methodology to classify copper tailings according to their potential as alkali-activated materials (AAMs) for construction applications. The methodology includes geochemical and mineralogical characterization via QEMSCAN and X-ray fluorescence, with mechanical performance evaluation through compressive strength test (UCS). A three-phase diagram based on Al2O3, Fe2O3, and CaO-MgO-K2O is proposed for a fast screening of copper tailing potential to be used as a construction material. In this paper, three copper tailings were chosen to test the methodology, and a set of five samples for each tailing have been geopolymerized for testing. Copper tailing samples were mixed with 0, 2.5, 5, 7.5 and 10% by mass of Ordinary Portland Cement (OPC) to evaluate the effect on performance when a chemical co-activator is used to improve material reactivity. Compressive strength testing was applied on 2 cm3 cubes after 28 days of curing at 60 °C, yielding values from 6 to 26.1 MPa. The best performing sample featured a Si/Al ≅ 3 ratio and a mineralogy with significant presence of reactive species such as plagioclase and K-feldspar (≅42%). In contrast, high levels of Fe2O3 (≥12%), clay (≥7%), and pyrite (≥4%) were associated with reduced mechanical performance.

2025

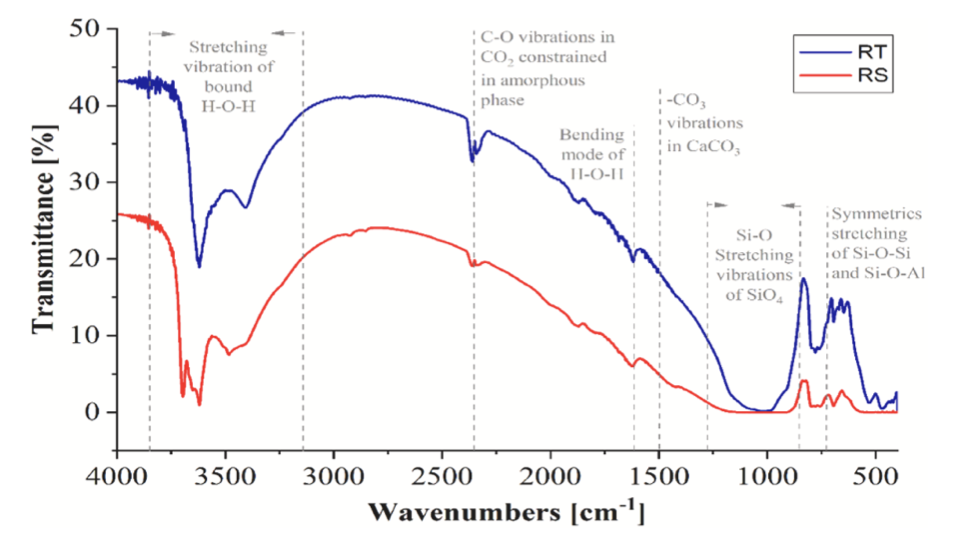

Effect of water as an alkali activator transport medium and other manufacturing factors in alkali activated copper mine tailings

Keywords: Alkali activated materials (AAMs); Copper tailings; Water-to-binder ratio; Curing temperature; Mechanical performance

Estefanía Loyola

Faiz Shaikh

Felipe Vargas

Abstract

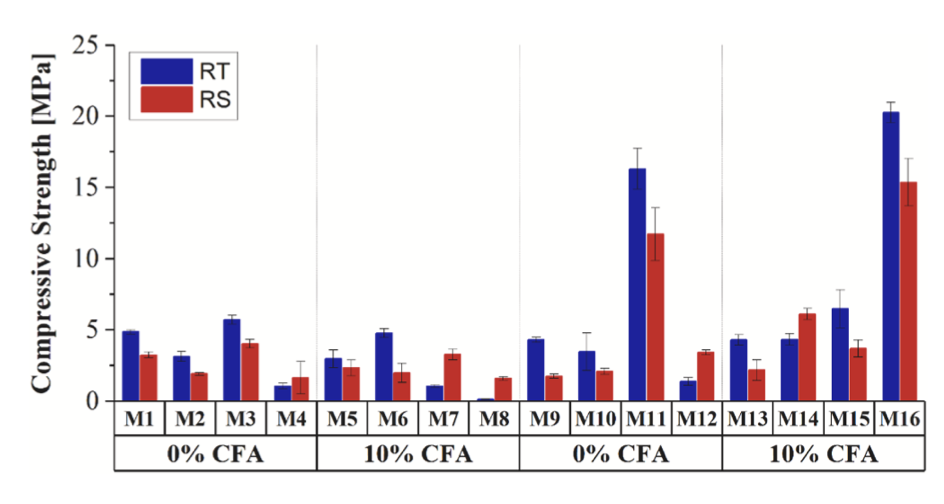

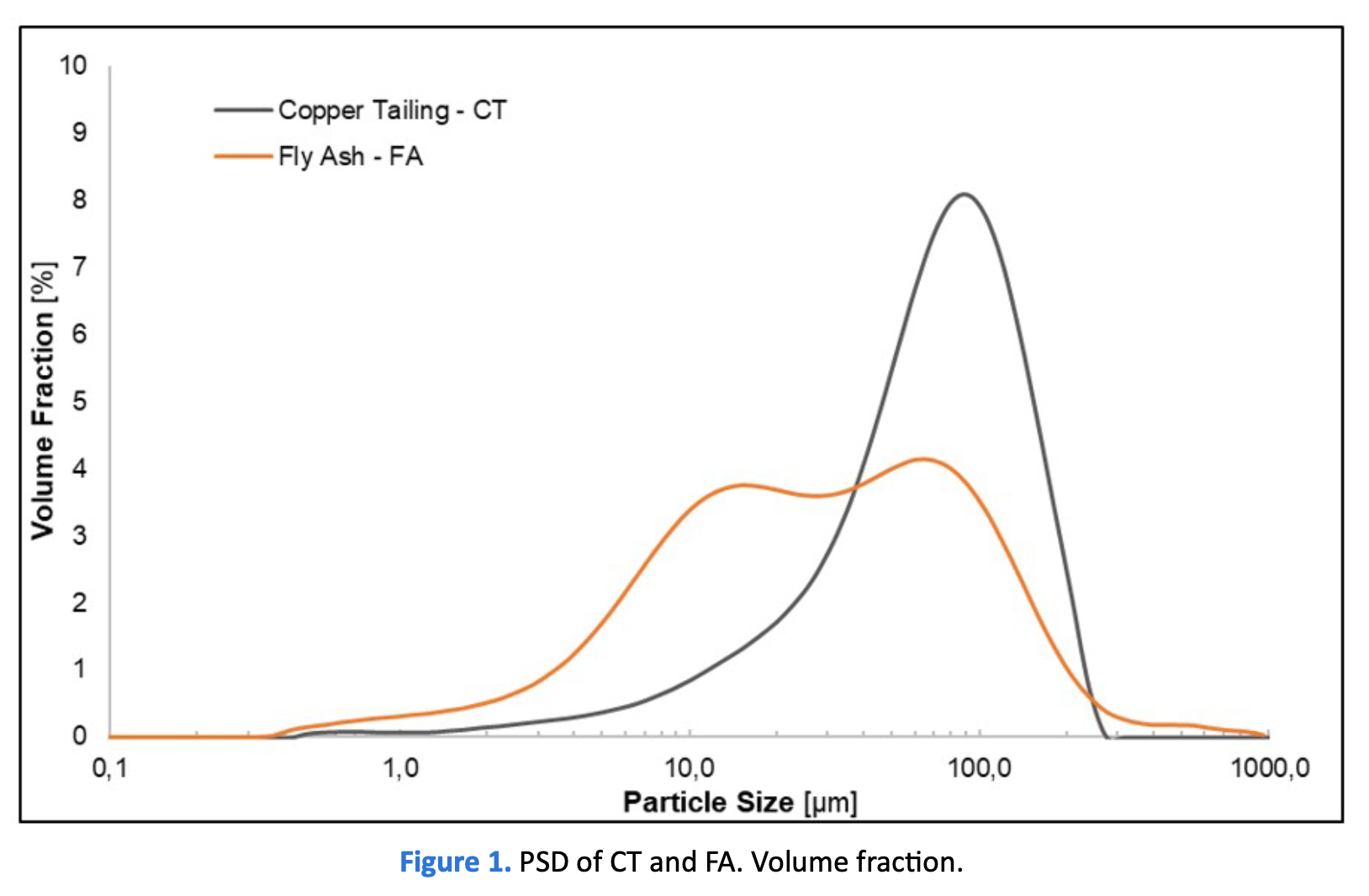

The copper mining industry generates approximately 200 tons of tailings for every ton of ore extracted. On the other hand, the construction industry has a significant carbon footprint associated with cement manufacturing. Use of copper tailings as precursor for alkali activated materials (AAMs) can reduce the environmental impacts of construction and mining industry. Nevertheless, low reactivity of tailings is a challenge to increase their use. Two copper tailings were used, and an experimental design was conducted to determine statistical relevance of factors such as co-activator use, molar concentration, water-to-binder ratio among others. Reactivity was evaluated using isothermal calorimetry and thermogravimetric analysis, and compressive strength at 28 days was measured. The chemical structure and particle size distribution are similar for both samples, resulting in low reactivity of the tailings, as observed in isothermal calorimetry and thermogravimetric tests. This low reactivity is attributed to their high crystallinity, which is also reflected in the mixes designed with them. However, with the appropriate combination of factors, such as the water-to-binder ratio and the concentration of the activator, it is possible to achieve samples with a compressive strength close to 20 MPa at 60 °C, with both tailings showing the best performance. Despite the similarities, one of the samples exhibited better compressive strength performance compared to the majority of the samples. This enhancement is associated with the presence of amorphous mineral species and clays.

2025

Use of Artificial fine aggregates from copper tailings in mortar

Keywords: Artificial fine aggregate, copper tailings, alkaline activated materials (AAMs), mortar, mechanical performance

Felipe Vargas

Guillermo Rios

Abstract

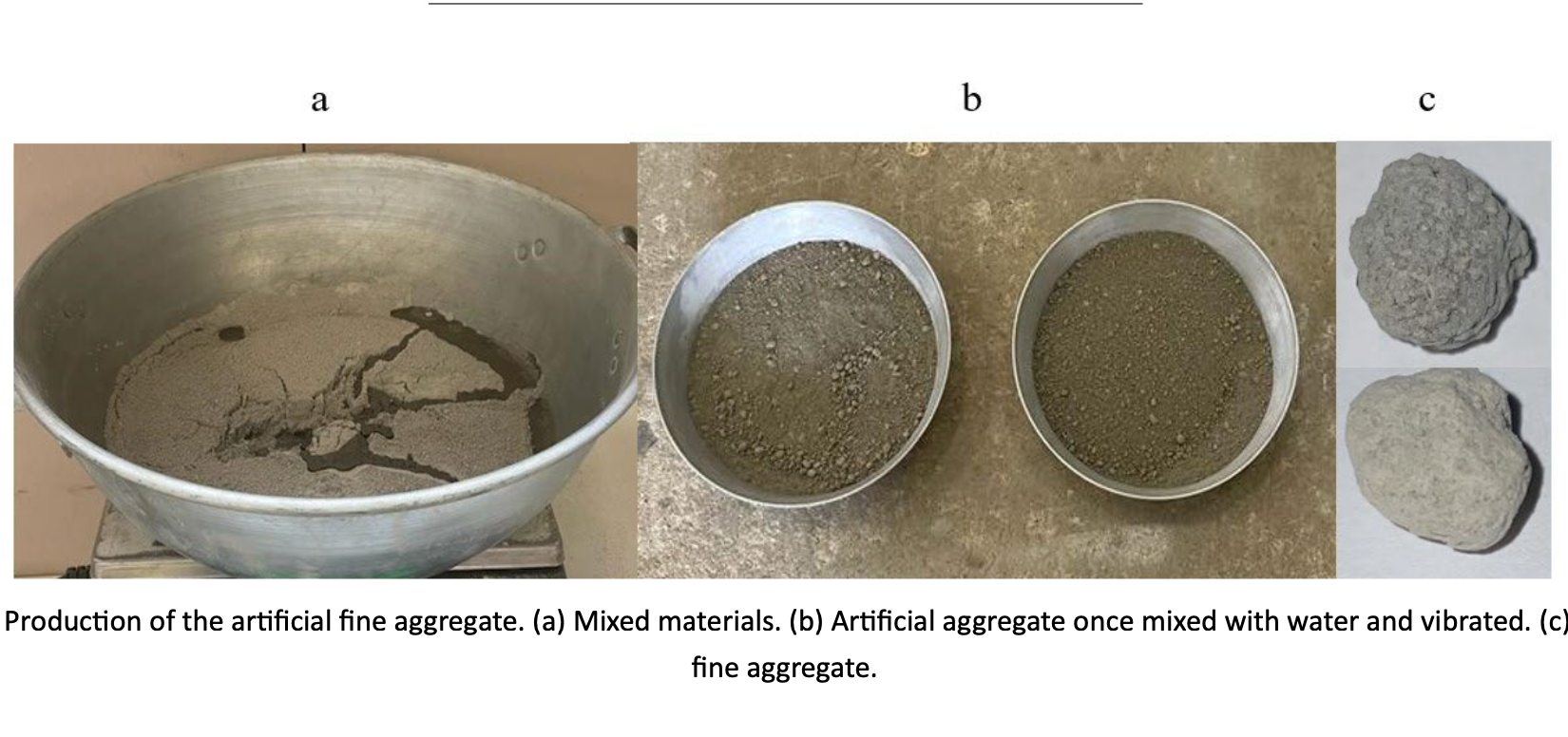

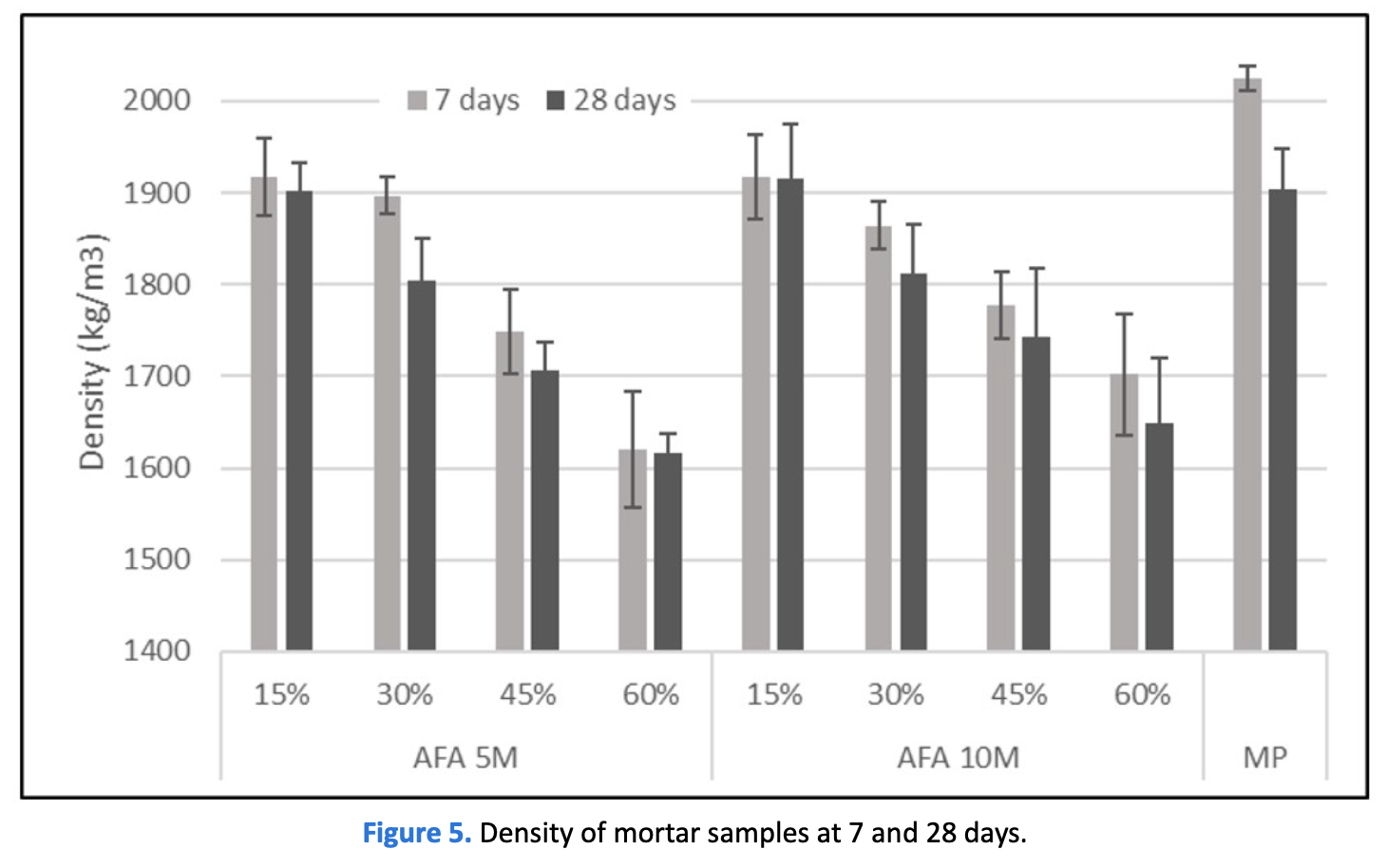

The construction and mining industries are among the most impactful on the environment. A significant issue in the mining industry is the generation of mine tailings, with copper tailings being among the most voluminous. One potential way to utilize them is as a replacement for fine aggregates, although they are extremely fine. Through an alkaline activation process, it is possible to agglomerate them and use them in mortar mixtures. This research used copper tailings to produce an artificial fine aggregate (AFA) through an alkaline agglomeration process and assessed its impact on mortar mixtures. The results demonstrate that it is feasible to manufacture an artificial fine aggregate by alkaline agglomeration using the proposed methodology. Also, it is shown that replacement levels up to 45% show improvements in the mechanical performance of the mortar mixes. Additionally, a decrease in the density of the mixtures was observed.

Conferencias

T2CM: Desarrollo de hormigones sustentables a partir de relaves mineros – Desarrollo & Escalamiento

Paper conferencia Hormigón – 2025

Alvaro Videla

Felipe Vargas

Iván Navarrete

Claudia Eugenin

Estefanía Loyola

Victoria Romano

Luis Morales

An Innovative Approach to Repurposing Tailings for Sustainable Construction

Paper conferencia Tailings – 2025

Claudia Eugenin

Estefanía Loyola

Luis Morales

Iván Navarrete

Felipe Vargas

Alvaro Videla